Your inventory is your biggest asset. But also your biggest liability. Why? If you’re not selling all of your inventory, you’re losing profits. So how can you get the most out of your inventory, in today’s current state? Let’s explore 4 ways, plus an easy solution when you need more stock of those popular items.

1) Optimize the Product Details Page

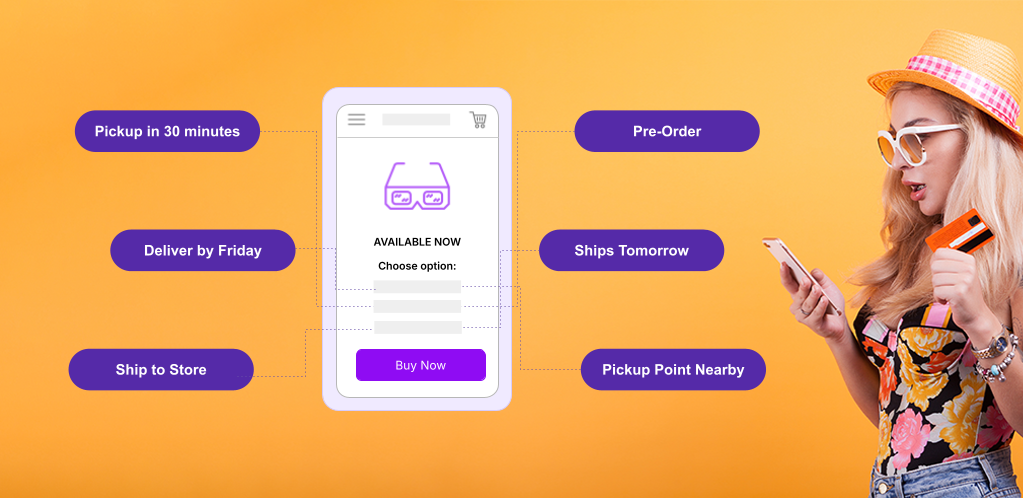

A trending comment out of NRF: Retail’s Big Show 2025 is that the Product Details Page (PDP) is the new home page. So make sure your PDPs are optimized to offer the best experience and increase a customer’s propensity to buy. Is the estimated delivery date correct? In-store pickup enabled? And don’t forget about personalization to sell MORE stock. Offer personalized product recommendations that are relevant to your customer and what they’re shopping for: a whopping 49% of consumers said they have purchased a product that they did not initially intend to buy after receiving a personalized recommendation. Even better? Purchases saw a 10% higher AOV when a recommendation was clicked.

2) Ship from Store

Enable Ship from Store on a larger scale to open up more inventory to your customers. You will need to know what inventory you have where, and ensure your plan is solid. Do you bulk ship items or orders from each store once a day? More often? Or maybe you want to transfer items from one store to another to meet regional demands? The right order management system (OMS) will allow you to make these changes as the days, and current market, ebb and flow.

3) Minimize Inventory Moves

At the same time, have a thoughtful approach to where you move inventory to, and don’t move it unless necessary. More often than not, the most cost-effective way to source and fulfill an order is shipping inventory from its current location in your network⸺whether that is from a warehouse, DC, or a store. With the right OMS, you can control every step in your fulfillment process. What does this mean? Apply specific sourcing rules so you’re always shipping orders from the best location—such as the store with the lowest sell through, oldest stock, highest discounts, or store closest to the customer.

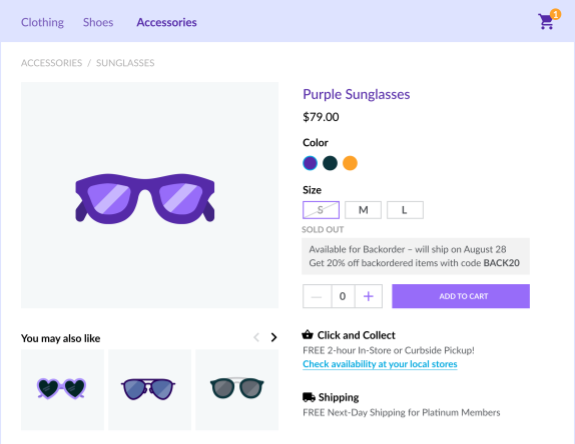

4) Accept Backorders

You may have some items temporarily out of stock, however more are already en route. But if an item is out of stock and you don’t list it on your website, you’re losing a sale. Instead of losing that sale, accept backorders of products that are temporarily out of stock. Even if that’s not your typical business model, this is the time to try a new tactic. If you can take a back order and communicate to your customer when it’s likely to be fulfilled, you’ll hold on to that customer you might otherwise lose.

Expand your inventory with Drop Ship Vendors

Need more inventory of a popular product but out of stock at your DCs and warehouses? Consider looking for a Drop Ship Vendor (DSV). They might already have the same product in stock, and can handle the fulfillment without impacting your current distribution centers or store network. To make this a seamless process both for your business and customers, ensure your OMS can easily track and manage all DSVs, and scale up or down as needed.

Summary

Even when markets are in flux, you can take back control of your inventory. Sell more. And maximize profits. All while ensuring you offer the best customer experience. Adopt one, or all, of these recommendations to boost your bottom line—and beat your competitors.

How can you execute on these tactics? With a distributed order management system. A modern OMS, like Fluent Order Management, is designed to flex with the needs of your business. Be agile in the wake of changing customer demands—or market needs. And allow you full control every step of the way. To learn how Fluent Order Management can support your business’ needs, contact us today and go live in as little as 8 weeks.